Operation principle

When 6YL series oil screw press machines operating prepared material enters extruding chamber from the hopper and then moves forwards by the rotating pressing screw and that is pressed.

Under the high-pressure condition in the chamber, friction between material and screw. Between material and chamber will be created, which also creates friction and relative movement among material particles. On the other hand, root diameter of the pressing screw caries larger from one end to the other, hence. When rotating, it not only pushes particles moving forwards but turns them outwards as well, meanwhile, particles adjacent the screw will rotating along with screw rotating, causing every particle inside the chamber to possess different speed. Therefore relative movement among particle creates heat which is necessary during manufacturing because of helping protein change property damage colloid, increase plasticity, decrease oil’ s elasticity resulting hing oil productivity.

Structure

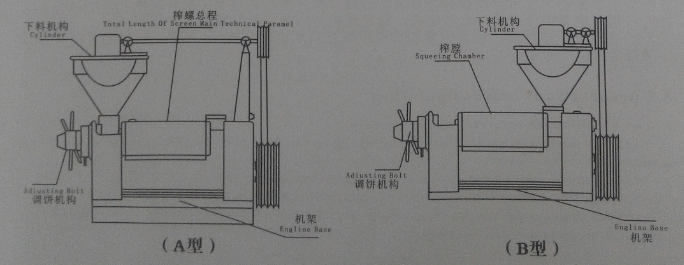

6YL series oil screw press machine has A,B two kinds of models, with the drive mechanism, frame, electric, adjustable cake institutions, negative pressure filtration system parts. As shown in figure.