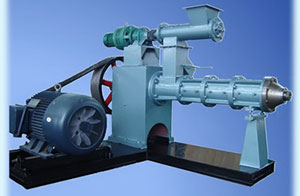

Extruder TXP-160 can be used for the expansion of rice bran, soybean, maize, rice powder and feed, etc, it’s appliable for the production of oil factory, rice factory, soybean protein factory, feed factory, etc. The machine is of big production capacity, low power consumption. After extruding, ricebran can keep fresh for two months, the extraction yield can be 30-45% higher, residual oil in extracted dry meal less than 1%, the protein content, color both better than granulating-drying-extracting process. After extruding, soybean can be deodorized, urea enzyme in soybean can be passivated, the extraction yield can be 45-50% up, the residual oil content in meal less than 0.8%, the protein content and color both better than drying-extracting process.

Extruder TXP-160 can be used for the expansion of rice bran, soybean, maize, rice powder and feed, etc, it’s appliable for the production of oil factory, rice factory, soybean protein factory, feed factory, etc. The machine is of big production capacity, low power consumption. After extruding, ricebran can keep fresh for two months, the extraction yield can be 30-45% higher, residual oil in extracted dry meal less than 1%, the protein content, color both better than granulating-drying-extracting process. After extruding, soybean can be deodorized, urea enzyme in soybean can be passivated, the extraction yield can be 45-50% up, the residual oil content in meal less than 0.8%, the protein content and color both better than drying-extracting process.

Extruding Principle

By squeezing, rubbing, shearing forces of pressing worms of unequal thread pitches in the extruding cage, the mechanial energy is converted into heat energy, forms certain pressure and temperature in the extruding cavity, from the outlet die head, the extruded material spray out and inflated .

Applications

1. Applicable for oil factory(15T/D Min.)

By inflating-extraction process, the crude oil is of light color and low acid value, help for the production of high quality edible oil.

The process flow of rice bran

Rice bran→clean→extruding for fresh-keeping→ extraction for oil production(the acid value of the ricebran after expansion will raise 1mgKOH/g oil in one month average.)

The process flow of soybean

Soybean→clean→softening→flaking→expansion→extraction

2. Applicable for soybean protein factory

Soybean→clean→softening→flaking→extruding for deodorizing and urea enzyme passivating→defatting→soybean protein(after extruding, the urea enzyme active index UA<0.4.)

3. Applicable for rice factory(200T/D factory Min.)

Raw rice→clean→hulling→separating→milling→rice bran→extruding for fresh-keeping→wrapping→oil workshop or feed workshop

4. Applicable for feed factory

Soybean→cracking→extruding for deodorizing→feed preparation

In above applications, according to different requirement of extruding, the temperature can be controlled in 80-140℃, the pressure can be controlled in 2-4 atm.by changing outlet die head or adjusting the distance between die head and pressing head. The expanded material can cut the water content by 3-5%.

Main Technical Data

1. Capacity(kg/h): ricebran 800-1000 soybean 1100-1400 feed 800-1000

2. Rotating speed of main shaft(r/min): 630

3. Feeding shaft speed(r/min): 200-400

4. Main motor power(kw): 55

5. Feeding motor power(kw): 2.2

6. Electric power consumption(kw·h/t): rice bran<45 soybean<35 feed<40

7. Noise dB(A): <80

8. Processing temperature(℃): 80-140

9. Dimension(L×W×H): 2150×2100×1280mm

10. Weight(kg): 1800

Above specification for reference only, actual numbers and functions are subject to instruction manual.

There maybe slight difference between pictures and actual products during the site construction.